Seat is disposed in the valve body in sealing engagement with the disk, gate, plug and ball. We can manufacture different kinds of valve seat. With an independent seal product design capabilities, customers only need to provide the use of working conditions, specifications, such as the basic requirements of the pound, VASAR can quickly provide customers a complete set of sealed program.What is more,We can also machining the seats as per customer's drawing.

Plastic Sealing Ball Valve Seat Design:Embedded plastic plug-in by the metal seat, the valve seat is fine finished, make sealing pair with sphere. The plug-in is Made from thermoplastics which is pressed in valve seat by press. The unique design which changed the traditional construction of locking rolling mode and clamp mode make the plug-in locked in groove. Then it reduces craft, ensuring dimensional tolerance, enhancing leakproofness of the plug-in. This valve choosing different materials according to valve application environment, medium, pressure, temperature, etc, to, can be used in different working conditions. The application size of valve is from 1/2 "to 60", the pressure 150 ~ 2500 lb.

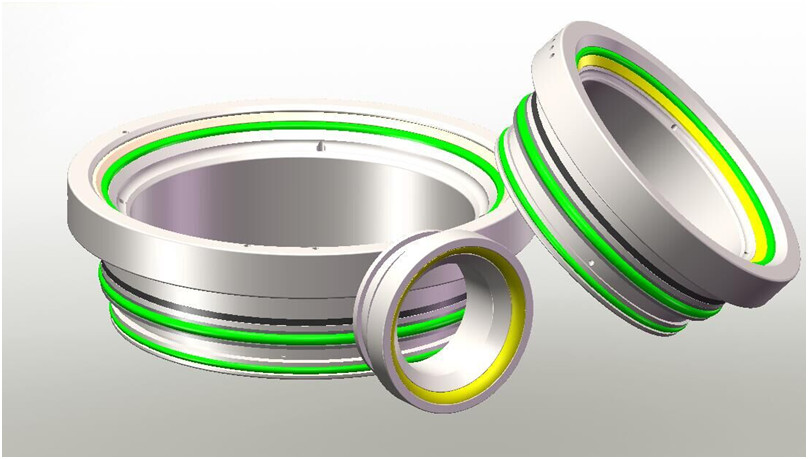

Rubber Sealing Ball Valve Seat Design:This valve seat embedded the elastic rubber ring make sealing pair with sphere, then is pressed Plastic plug-in which play protect and seal effect. The equivalent of adding a sealing pair, then it makes valve sealed better and applied ever more. In addition, VASAR chooses different materials according to the customer's working environment. It can be used under the condition of different operating conditions, work stress can be from 150 lb to 2500 lb.

Metal To Metal Ball Valve Seat Design:This valve seat adds surface coating outside, make sealing pair with sphere. According to the requirements of the different operating conditions, the surface coating can choose different materials. The valve’s seal adapts to some special working conditions, having a long service life, such as causticity and medium containing solid particles, etc. Common used coating materials include chemical nickel-plating, tungsten chromium cobalt alloy, tungsten carbide, etc. Due to the progress of technology, through unique grinding technology of VASAR, the metal valve can achieve zero leakage, solving the problem of sealed hard. The surface roughness of valve can reach 0.2 below.

PMSS Sealing Ball Valve Seat Design:This valve seat is embedded rubber inside and added surface coating outside, making two sealing pair with sphere. This kind of valve applies even wider, which ensures the stability of the seal by the first metal sealing pair and the second soft seal. The design makes the lifetime of the valve longer and maintenance-free.